- Home

- Knowledge center

- Blog

- How to choose the best warehouse management system?

Blog

HOW TO CHOOSE THE BEST WAREHOUSE MANAGEMENT SYSTEM?

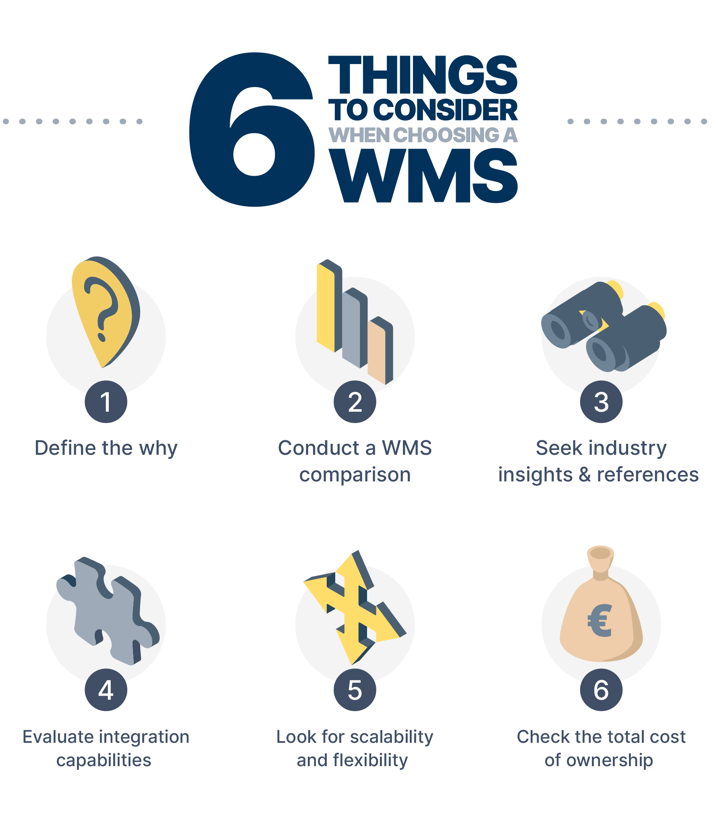

When it comes to modern warehousing, finding the best warehouse management system (WMS) is a vital decision for businesses seeking operational excellence. The question is: how to choose the best WMS system? With plenty of warehouse management software out there, it's essential to think about different factors before settling on a solution. In this blog post, we discuss six important things to consider.

#1 Define the “why”

Why do you need a warehouse management system? This question might sound trivial, but the devil is always in the details. Building upon solid principles is essential for making a good choice. So, before starting the WMS selection process, make sure you understand your unique business needs. Assess your warehouse operations and identify the key functionalities and features you need in a WMS. By listing these needs upfront, you can ensure your chosen software is tailored to your business.

Useful questions to ask:

- What characterizes your current inventory in terms of quantity and quality?

- What aspects contribute to the complexity of your orders, and how would you assess their level?

- How would you describe your current fulfillment processes? Which areas require improvement or optimization?

- What existing software systems (e.g., ERP, TMS, etc.) do you currently have in your warehouse?

- Are there any specific industry requirements or regulations your warehouse operations must comply with? (e.g., working with dangerous goods)

- What are your expectations or plans for future growth regarding inventory, order volume, or operational capacity?

#2 Conduct a WMS comparison (warehouse management systems comparison)

Perform a comprehensive comparison of various warehouse management systems available in the market. Evaluate their features, functionalities, and performance in addressing your specific needs. Compare user-friendliness, automation capabilities, reporting and analytics tools, order management functionalities, and how the systems track inventory. Consider factors like customization options, ease of implementation, timeframes, and vendor support.

#3 Seek industry insights & references

Opinions count. Just like we value others' feedback on movies or restaurants, industry opinions are crucial when looking for the best warehouse management system. Therefore, reach out to industry peers and attend trade shows to gather real-world feedback and reviews from businesses using different top WMS systems. Their insights can provide valuable perspectives and help you make an informed decision.

In addition, once you have compiled a list of possible WMS vendors, research their background, including their industry experience and the number of successful implementations they have conducted. Evaluate their reputation and customer reviews to ensure their reliability and ability to provide ongoing support. A reputable and experienced vendor is more likely to deliver a robust and dependable WMS solution.

#4 Evaluate integration capabilities

Seamless system integration is vital for a modern warehouse. During the WMS selection, evaluate the compatibility of the software with your existing software systems, such as ERP or TMS solutions. Also, consider future integration needs, like implementing warehouse automation. Can the WMS support these plans?

Efficient integration ensures uninterrupted data flow, eliminates manual data entry, and provides comprehensive visibility across your business operations. Opt for warehouse management software that excels in seamless integration to avoid potential issues.

#5 Look for scalability and flexibility

Warehouses are dynamic environments that undergo changes over time. Your WMS should be equipped to handle these transformations seamlessly. That is why it is important to look for a flexible and scalable solution that can accommodate your evolving needs, e.g.:

- managing increased inventory volume

- accommodating additional warehouses or distribution centers

- supporting the integration of new business channels

The best warehouse management software empowers your business to embrace growth opportunities, ensuring minimal disruptions and seamless transitions into the future.

#6 Check the total cost of ownership

During the WMS softwares comparison, check the total cost of ownership (TCO), including upfront costs, licensing fees, ongoing maintenance, and support charges. A comprehensive understanding of the TCO will help you make an informed decision.

Additionally, consider the potential return on investment (ROI) too. Factor in the long-term benefits the WMS system may provide, e.g., savings in labor costs, improved inventory management, faster order fulfillment, and reduced errors. Aim for a system that offers a favorable balance of upfront costs and ongoing operational advantages.

Summary

Choosing the best warehouse management system is a critical decision that can significantly impact your warehouse operations and overall business success. Assess needs, compare WMS solutions, seek feedback, and consider integration, scalability, and costs. Remember, the best WMS is the one that aligns with your unique requirements and empowers your business to thrive in the competitive world of modern warehousing.

Are you currently exploring options?

Our WMS solution Astro WMS® is designed to support your long-term needs: it is scalable, rich in configurable core features and functionality, and adaptable across multiple sites. In addition, it can easily be integrated with any supplier’s automation equipment, giving you the freedom to choose when implementing a warehouse automation solution.

EXPLORE ASTRO WMS®

FAQ

Why is selecting the right WMS important?

Choosing the appropriate WMS is crucial for optimizing warehouse operations, enhancing efficiency, and supporting business growth. A well-suited system aligns with your specific operational needs and future objectives.

What factors should I consider when selecting a WMS?

-

Defining your business needs: Understand your inventory characteristics, order complexities, fulfillment processes, and areas needing improvement.

-

Comparing WMS options: Evaluate features, user-friendliness, automation capabilities, and vendor support.

-

Seeking industry insights: Search for references and gather feedback from peers and industry experts.

-

Assessing integration capabilities: Ensure compatibility with your existing systems, like ERP or TMS.

-

Evaluating scalability and flexibility: Choose a system that can adapt to future growth and changes.

-

Considering costs: Check the total cost of ownership (TCO) and the potential return on investment (ROI). Balance upfront expenses with long-term operational benefits.

How do I assess my warehouse's specific needs?

Why is integration capability important in a WMS?

A WMS must seamlessly integrate with existing systems (e.g., ERP, TMS) to ensure smooth data flow, eliminate manual data entry, and provide comprehensive operational visibility. This integration is vital for maintaining efficient and error-free processes.

How does scalability affect my WMS choice?

Selecting a scalable WMS ensures that the system can grow with your business, accommodating increased inventory, order volumes, and operational complexity without requiring a complete system overhaul.

What role does vendor reputation play in selecting a WMS?

A vendor's industry experience, proven implementations, and customer reviews reflect their reliability and ability to provide expert guidance and ongoing support—critical for a successful WMS deployment.

How should I approach cost considerations for a WMS?

Balance upfront costs with long-term benefits, such as labor savings, better inventory management, and reduced errors. Focus on a system that delivers a strong return on investment over time.